Free Download ANSYS 2019 Full Version for Windows PC. It offers a complete simulation workflow that will allow you to transform your R&D for metal AM efforts into a successful production operation.

The ANSYS 2019 Additive Benefits

The additive manufacturing process (3D printing), which produces three-dimensional objects layer by layer, is a technique that uses a wide range of materials. In recent years, additive manufacturing has gained popularity as a real manufacturing process. A digital file is sent to a machine that converts an engineering design into 3D printed parts. AM was initially used as a rapid prototype method – a faster way to make (mostly plastics) parts, before they were manufactured using well-accepted manufacturing methods, such as casting, injection molding, forming, and joining.

In the 1990s, metal-based AM was developed. In the 1990s, several companies developed laser sintering machines that allowed metal parts to be 3D printed directly. This was an alternative to multi-stage direct manufacturing processes. SLS is a technique for additive manufacturing that uses lasers to melt metal or polymer powder. The laser targets specific points in space that are defined by the 3D model and binds powder together to form a solid structure.

The ANSYS solution was designed specifically for these users.

- Aerospace OEMs & Suppliers

- Metal AM print services bureaus

- Biotech companies with AM initiatives

- Automotive OEMs and Suppliers

- Companies that R&D AM materials

- Metal AM machine manufacturers

Additive Features of ANSYS 2019

- Create parts and structures impossible to manufacture using traditional methods. For example, parts with complex internal structures or organic shapes. One AM-generated component can replace a multi-part assembly. Parts can be produced and designed for improved performance and more efficient material use.

- Producing replacement metal parts on demand without the need of an entire factory or multiple machines.

- Novel materials with unique properties are produced.

- Replace worn-out or broken parts no longer produced. Deposition processes allow for new functionality to built onto existing components, opening new opportunities for remanufacturing.

- Design for AM (DfAM), utilizing topology optimization, lattice structures

- Conduct design validation

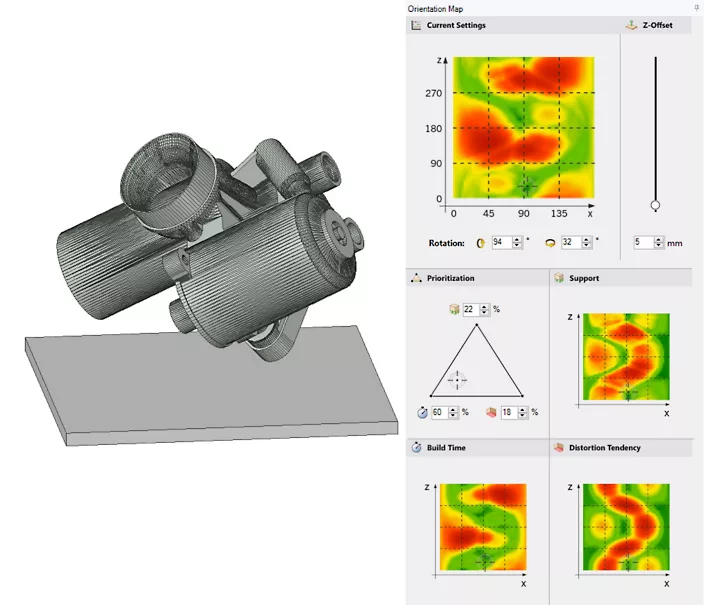

- Build setup improved — includes additional design features, such as part orientation and automatic creation of physics-based supports structures

- Simulate the print process

- Learn more about materials and their properties

Technical Details and System Requirements

- 1-2 CPUs, 4-12 physical cores each

- 16GB RAM (minimum), 64GB+ recommended

- 2TB+ hard drive space

- Workstation graphics card

- OS: Windows 7/10